Direct coupling of the payload to the motor eliminates the need for mechanical transmission elements. No mechanical wear results in excellent reliability and long lifetime, while having fewer mechanical parts minimizes maintenance.

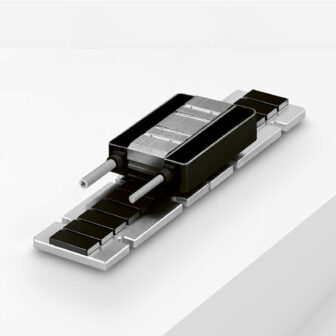

Linear motors

We offer the industry’s most comprehensive range of standard linear motors, comprising over 40 models to meet a diverse array of requirements.

Our linear motors

Below is an overview of our linear motors