WINGLET

WINGLET is a Windows-based software designed to work with our AccurET/UltimET controllers, offering robust performance visualization, automated testing, and efficient troubleshooting capabilities.

This system serves various users throughout the process of device development and deployment, assisting them in design optimisation, manufacturing robustness and field service operations.

Its functions are designed to improve machine performance, ensure manufacturing reliability and facilitate accurate diagnostics.

Characteristics

- PC-based software compatible with ETEL AccurET / UltimET controllers

- Streamlines setup and qualification from R&D design to end-user

- Automated testing and reporting to ensure manufacturing robustness

- Provides fast and precise machine diagnostics for improved efficiency

Diagnostic

User friendly environment

Advanced tools

Powerful software tool for automated test and simulation

Here are the key features:

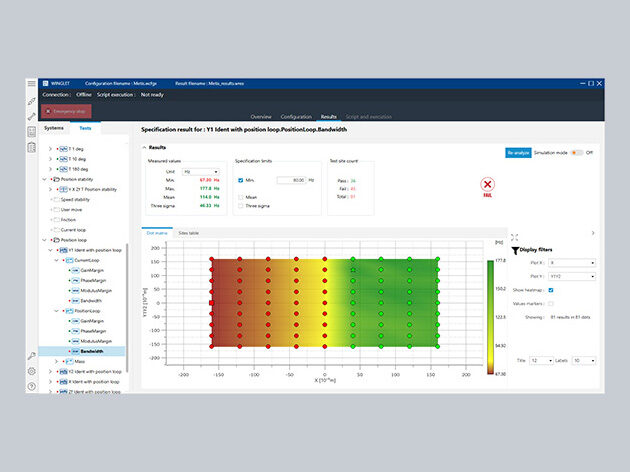

WINGLET enables the measurement and display of key motion specifications, such as Move & Settle and Jitter, across the entire workspace. It allows for easy tuning of control parameters and simulation of their effects, saving time during the fine-tuning phase.

A significant portion of WINGLET is dedicated to automated testing and series production qualification of motion systems and equipment. It runs user-defined test choreographies, compares results with specifications, and provides pass/fail status, streamlining qualification processes from production to installation.

In complex equipment issues, WINGLET helps minimize downtime by executing predefined sets of tests to visualize motion system behavior. Its user-friendly interface enables users to conduct tests without specialized skills, facilitating easy reporting and result sharing between field service and headquarters.

The full-featured version for OEMs allows creating/editing test choreographies, defining/editing pass/fail criteria, and tuning control parameters and simulations. It is suitable for OEM headquarters, R&D teams, and key users.

A lighter version installed on equipment for end-users allows full execution of tests and results visualization but restricts editing capabilities to prevent modifications of choreographies, criteria, or results. It is intended for local service personnel during installation, maintenance, or troubleshooting.

Downloads

| Product | ||

|---|---|---|

WINGLET | Documents | |