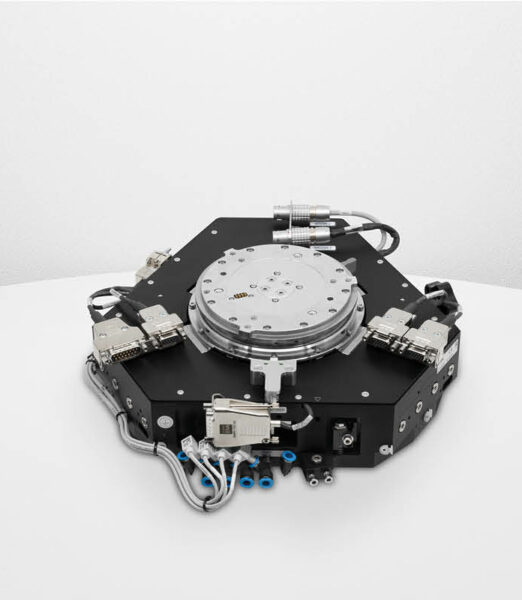

Z3TM+

The Z3TM+ module expands the range of motion platforms and integrates four independent degrees of freedom and an optional lift pin mechanism.

This module revolutionises motion control in the semiconductor industry through its advanced design with four degrees of freedom housed in a single module. With optional coarse Z-axes, this module provides unprecedented control over wafer motion profiles and improves precision and efficiency in semiconductor manufacturing.

Utilising flexure-based fine Z-axis technology, hysteresis issues are avoided while achieving nanometre-level resolution, accuracy and repeatability with higher dynamics. Embedded support for sample alignment further enhances process control and enables users to achieve unrivalled performance at wafer level.

Characteristics

- Stroke: Z: ±2 mm, CZ: 12 mm, Rx/Ry: ±0.08° and Theta 364°

- Move and settle time: Z: 100µm @ 50nm in 60 ms / Theta: 1° @ ±40µdeg in 70 ms

Bidirectional repeatability

Position accuracy

Position stability

Z3TM+ combined module

Here are the key features:

In many inspection systems, a Z axis is used to move the process tool to the right altitude. In high-end applications, these process tools can be very heavy and movements are often required during process to best follow the processed surface. The low bandwidth resulting from such a strategy is limiting the throughput of the machine. With Z3TM+, by moving the lighter substrate instead of the heavy process tool. Bandwidth is greatly increased and higher throughput can be sustained.

Many applications requirre not only a precise XY location but also orthogonality to the process tool, which can be difficult to achieve with a “traditional” stacked architecture. With Z3TM+ however, and thanks to its Z, Rx and Ry capability, native system errors comming from the stage can be mapped and compensated. This ensures the point of interrest is allways in the optimal position and orientation for being processed.

Z3TM+ comes with 4 fully integrated and independant vacuum lines. These lines are compatible with the 364° theta stroke.

This module also comes with a 3-point electrical lift-pin mechanism to ease wafer loading and offloading.