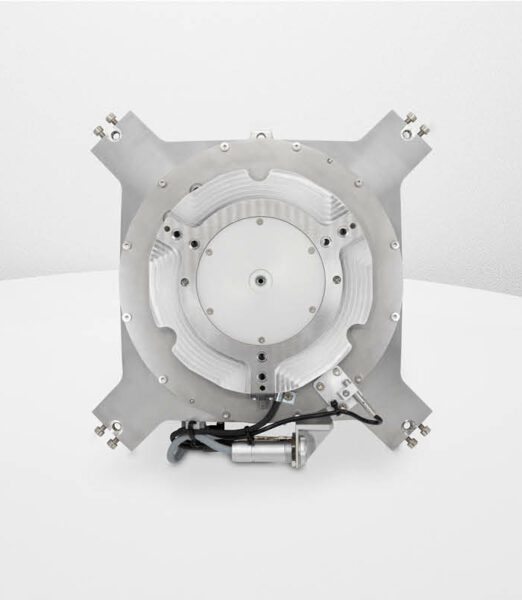

DXRH

Our latest rotary axis solution, the DXRH, 1 degree of freedom (DOF) mechanical bearing design, is characterised by exceptional accuracy.

The DXRH is characterised by its encoder system and unrivalled mechanical properties comparable to those of air bearing solutions – without the associated complexity. Supported by HEIDENHAIN best in class encoder and bearing technology and our toothless direct drive motor, the DXRH ensures precise performance without torque ripple.

Full compatibility with our standard interfaces enables seamless integration and performance upgrade without the need for redesign.

Characteristics

- Bidirectional repeatability: ±0.25 arcsec

- Position accuracy down to ±3 arcsec (w/o calibration)

- Position stability: ±2,5 marcsec

- Radial runout: ±1 µm

- Total axial error: ±2 µm”

- Up to 12.5 kg payload

- ISO 1 clean room compatibility

- 360’000 period / turn encoder

Bidirectional repeatability

Position accuracy

Position stability

DXRH Rotary Axis

Here are the key features:

Through the use of a highly stiff bearing, the DXRH module provides a runout reduced to 1 µm, which allows rotary motions to generate much smaller errors.

Through its ergonomic fixation flexures, the DXRH module warrants a thermal decoupling between the rotary module and the XY stage, which translates in a widely improved thermal stability of the inspection area’s surroundings.

With a 360,000 line encoder, the DXRH theta module comes up with an even more precise feedback device which fits even the most demanding motion accuracies.

The DXRH theta module comes with integrated vacuum tube connections, allowing the use of additional succion lines to prevent particles from reaching the processing area. This allows for operations into ISO1 level environments.

The DXRH theta module limits the payload to be carried by the XY stage and the height of the bridge that carries the processing elements (optics, laser…). This way, the Abbe error is reduced, improving the overall efficiency of the process. Also, the forces needed on the XY stage are reduced, making it the ideal choice for high-precision applications.

Downloads

| Product | ||

|---|---|---|

DXRH | Documents | |